Everything you need to know about PAC 600

Is PAC 600 compliant with European Regulation EU 2025/40 (PPWR)?

Yes: PAC 600 meets recyclability and waste reduction requirements thanks to its mixed cardboard and film packaging, which is fully recyclable and complies with European requirements.

Is PAC 600 film recyclable and made from recycled materials?

Yes, the film used by PAC 600 is considered 100% recyclable according to European standards. In 2018, CEREC confirmed that PAC 600 packaging with film is fully recyclable, as the film can be easily separated from the cardboard.

EU regulations stipulate that packaging must consist of:

- 35% recycled material in 2030,

- 65% in 2040 for plastic packaging not subject to specific constraints.

The PE films offered by PAC 600 currently contain around 50% recycled material, which already meets the 2030 requirements and anticipates those of 2040.

Does PAC 600 reduce the amount of packaging used?

Yes, thanks to its design:

- PAC600 cardboard uses less material than other common packaging (trays, American boxes),

- the film replaces bulky cushioning materials,

- combined with JIVARO, a more compact package is obtained with less material.

Is the final packaging easy for consumers to sort?

Yes. Consumers can easily separate:

- the film (recyclable),

- the cardboard (recyclable).

And even if they don’t, sorting centers can separate the materials.

Does PAC 600 help reduce transport returns due to breakage?

Yes, the combination of film and cardboard creates a rigid and secure box, which:

- protects fragile products,

- immobilizes heavy products,

- minimizes returns,

- avoids repackaging and therefore additional packaging.

For which types of products is PAC 600 the ideal solution?

Products requiring enhanced protection:

- electronic components,

- perfumes and cosmetics,

- tools,

- fragile or sensitive goods.

Can PAC 600 be integrated into an automated environment?

Yes. It integrates perfectly into:

- existing conveyor lines,

- robotic environments,

- preparation systems at stations or goods-to-person systems.

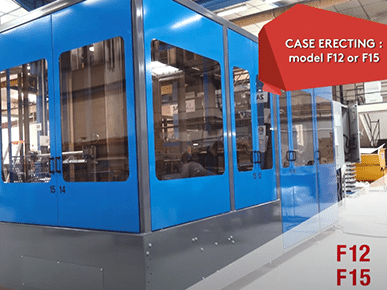

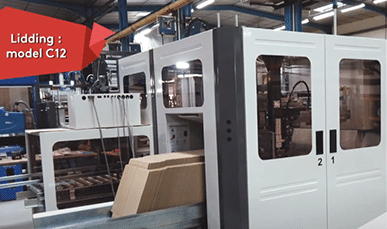

What speeds can PAC 600 reach?

Up to 16 cartons per minute for PAC600 carton forming, and up to 24 cartons per minute for lid placement.

Does PAC 600 reduce packaging costs?

Yes, by combining the following benefits:

- reduction in the amount of cardboard used,

- elimination of the need for cushioning,

- less breakage, therefore fewer returns and less repackaging required.

Does PAC 600 improve the company’s environmental image?

Yes, because it demonstrates:

- a reduction in over-packaging and cushioning,

- 100% recyclable packaging,

- anticipation of PPWR obligations,

- clean and robust packaging.