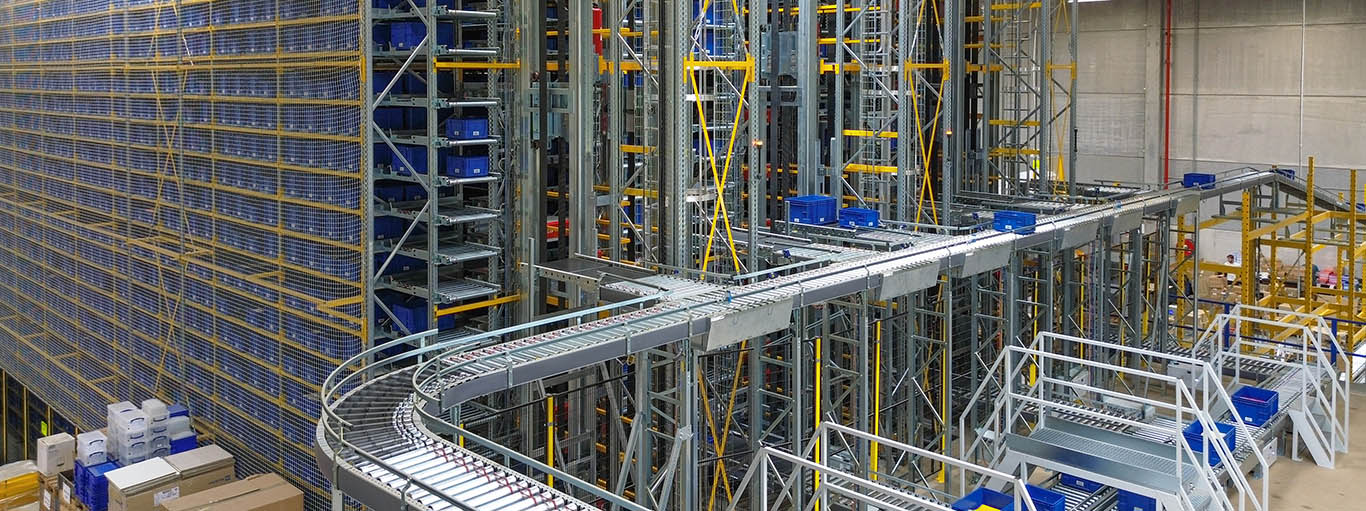

What are the advantages of automated storage compared to traditional storage?

The main benefits are:

- Space savings thanks to vertical use and reduced traffic areas,

- Increased efficiency with rapid availability of products for picking or shipping,

- Reliability through reduced handling errors and improved traceability,

- Productivity thanks to high throughput rates and continuous automation of flows.

What are the main automated storage technologies offered by SAVOYE?

SAVOYE offers a complete range of solutions tailored to every need:

- X-PTS shuttles for light loads at high speeds,

- HAIPICK by SAVOYE, mobile goods-to-person robots,

- MAGMATIC, single and double depth pallet shuttles,

- AS/RS (automated storage and retrieval systems and miniloads),

- Pallet Shuttle, multi-depth shuttles for pallets.

What are the uses of automated storage?

Automated storage can be adapted to several uses:

- Picking supply (goods-to-person, goods-to-robot),

- Buffers for finalized bins and packages to sequence palletizing,

- Pallet buffers for preparing shipments according to carrier departures,

- Reserve storage to optimize the storage of incoming pallets.

Is automated storage suitable for cold or frozen environments?

Yes. Certain solutions, such as MAGMATIC shuttles, can operate in refrigerated or frozen environments, ensuring operational performance even in extreme conditions.

Can automated storage be installed in an existing warehouse?

Absolutely. The solutions are modular and scalable, designed to integrate into new buildings as well as existing warehouses. They allow you to make the most of the available volume and adapt to the constraints of the site.

How do you choose the right automated storage technology for your business?

The choice depends on several criteria:

- Type of logistics units (containers, cartons, pallets),

- Volume of references and expected throughput,

- Space constraints (single, double, or multi-depth),

- Operational context (goods-to-person preparation, shipping, long-term storage).

SAVOYE will help you define the most appropriate solution for your strategic needs.