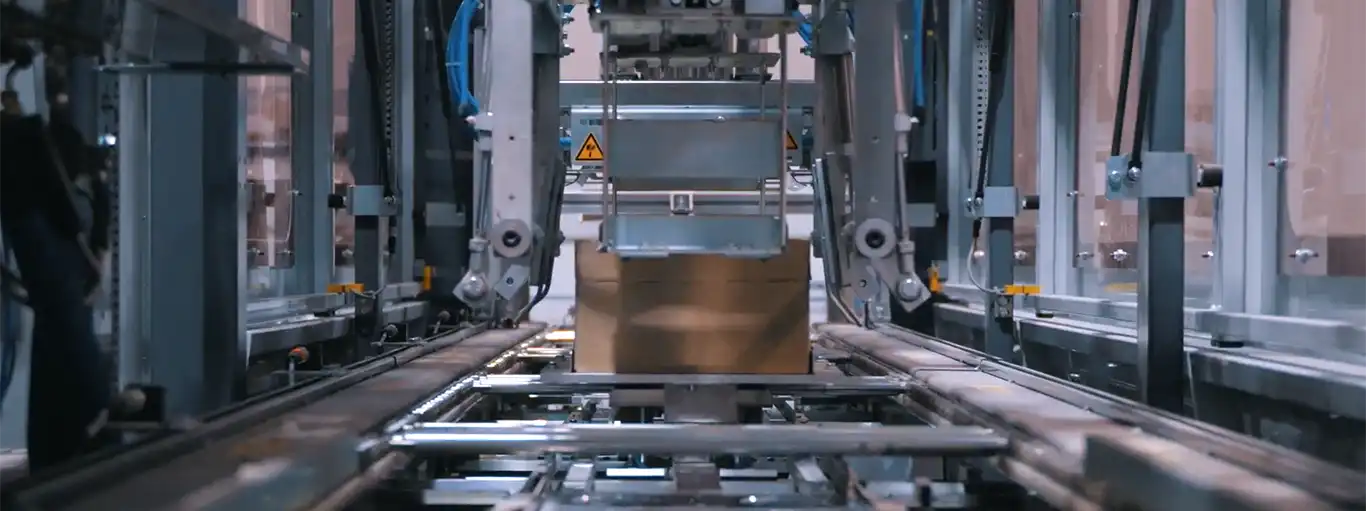

What is an automated packaging machine?

An automated packaging machine handles all or part of the order packaging process: forming packages, securing products, adjusting box height, and closing boxes. This equipment reduces costs, increases productivity, and improves the reliability of the logistics process.

Why automate your packaging processes?

Automating packaging has several advantages:

- Responsiveness thanks to package preparation as close as possible to carrier departures,

- Securing fragile or high-value-added products,

- Reduction in empty space transported and therefore logistics costs,

- Improved customer experience with carefully prepared, personalized, and eco-friendly packages.

What automated packaging solutions does SAVOYE offer?

SAVOYE offers a complete range of machines adapted to different needs:

- JIVARO, to reduce package volume and customize packaging,

- PAC 600, to protect fragile products and secure shipments,

- Tray formers, for fast and flexible box forming,

- Automatic document insertion, for inserting invoices, delivery notes, or commercial documents.

Which sectors can benefit from automated packaging?

Automated packaging solutions are suitable for many sectors: e-commerce, retail, B2B, specialized distribution, and industry. They are particularly well suited to companies with high order volumes that require speed, reliability, and cost optimization.

Does packaging automation reduce environmental impact?

Yes. By adapting the size of packages to the products being shipped, machines such as JIVARO reduce the amount of empty space transported and the number of trucks required. In addition, the use of 100% cardboard padding and packaging improves environmental responsibility and limits the use of plastics.

Are automated packaging machines customizable?

Absolutely. Some solutions allow you to customize packages (logos, messages, specific designs), thereby strengthening your brand image and customer experience.

Can automated packaging machines be integrated into an existing line?

Yes. SAVOYE solutions are modular and designed to integrate easily into existing processes, whether in mechanized, semi-automated, or highly robotized environments.

Are SAVOYE automated packaging machines compliant with European regulation EU 2025/40?

Yes. SAVOYE automated packaging solutions now comply with EU Regulation 2025/40 by automating the creation of perfectly fitted packages, eliminating empty spaces and unnecessary materials, while ensuring traceability through integrated QR code labeling. This not only allows you to ensure long-term compliance, but also to transform this constraint into a lever for logistical efficiency.