Why pursue automation?

Numerous reasons for automation exist, corresponding to various business contexts. However, as evidenced by the growing number of projects, certain motivations emerge with remarkable consistency.

1# Address the evolving demands of online commerce

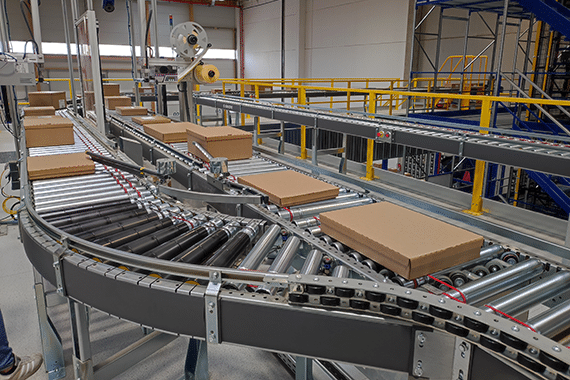

It has become increasingly common for consumers to place online orders on Sunday evenings for delivery on Monday mornings. This practice exemplifies the current expectations of a supply chain: speed, flexibility, and customization. Some customers desire a gift message, others prefer a simplified return process, and still others request special packaging. This fragmentation of expectations complicates preparation, and in light of this pressure, traditional methods are revealing their limitations. Automation enables the fulfillment of these demands without faltering, all while ensuring customer satisfaction.

2# Alleviate teams and realign skills

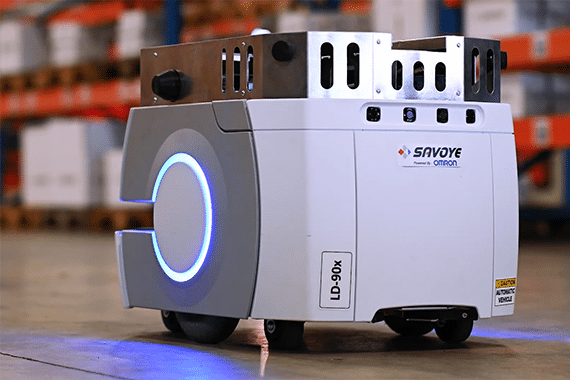

It is also essential to consider the human aspect. Working in a warehouse is physically demanding. Lifting heavy loads, extensive walking, and repetitive motions are all factors that can lead to issues such as recruitment challenges and increased sick leave.

By automating specific labor-intensive tasks, we enhance working conditions, enabling operators to focus on areas that demand judgment, expertise, or oversight.