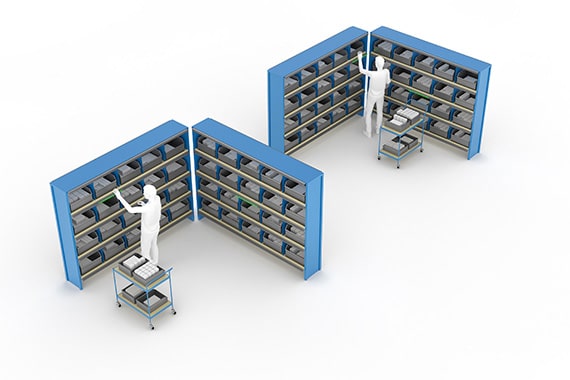

Smart furniture to facilitate the work of your operators

Efficient order picking must go hand-in-hand with smart, user-friendly tools. That’s what Savoye offers, with a range of picking tools that will let you:

- Increase the reliability of picking and sorting tasks

- Improve performance by using light to guide operations

- Make work more comfortable for operators and limit repetitive strain injuries

Savoye picking tools are equipped with LED technology and illuminated displays, to simplify picking operations while helping to reduce error rates.