The traditional WCS performs relatively well when controlling a simple system, but its limitations become apparent in a much more complex order fulfillment context. When several automated order fulfillment processes are combined or run in parallel, a common scenario in omnichannel Supply Chain organizations, the level of synchronization necessary for a system to apply the right control at the right time becomes much higher.

In such contexts, the capabilities of a traditional WCS expands to a WES (Warehouse Execution System), integrating smarter features to synchronize the flow of orders and optimize the automation in real time. What can this do for you? Improving the utilization of automation by redirecting tasks according to resource availability, and above all, providing additional capacity and flow.

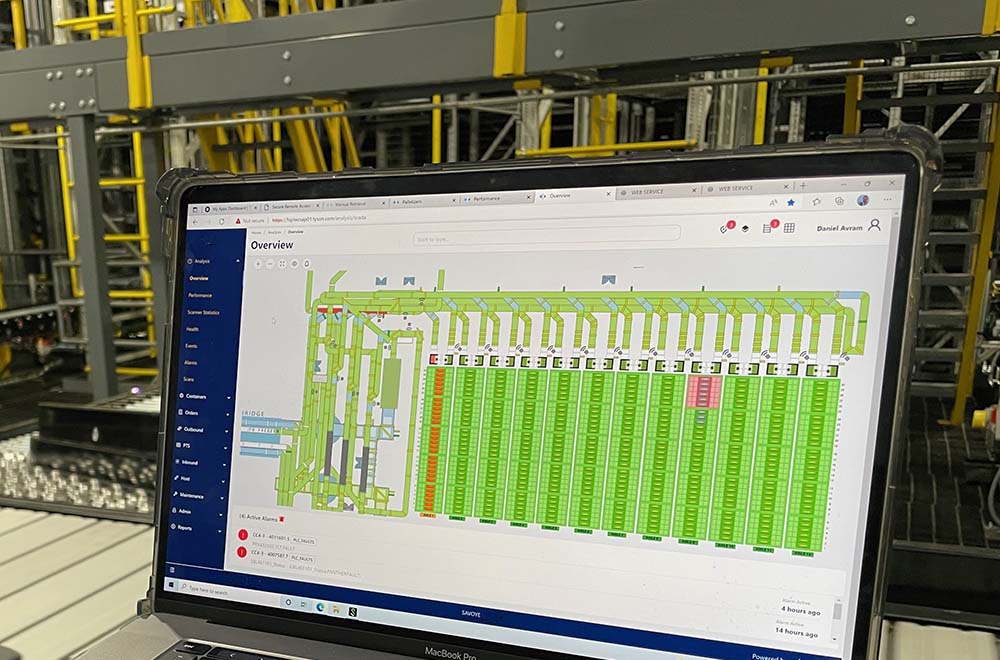

- The WMS will orchestrate the overall warehouse activity according to the volume of orders to be picked, available labor, and carrier departures, but it does not have detailed knowledge of the status of the robots and automated devices. That is where the WES contributes via continuous real-time communication with the control units (Controls/PLCs) and scanning devices (camera, barcode scanner).

- Based on the order profiles sent by the WMS, the WES will use built in algorithms to select the best sequence of boxes, bins, or pallets. This optimized selection is not only based on the priority level of each order, but also on the operating mode and the actual availability status of the devices that will perform the work. Operation with or without waving, calling a product category with affinity to several orders being picked, detection of saturation conditions in a zone, etc. These key performance indicators, technical as well as logistical, are integrated into the algorithms of the WES to achieve maximum fluidity of system operation. The launch mechanism is optimum, allowing dynamic rescheduling of the activity.