Optimizing intra-logistics using the digital twin

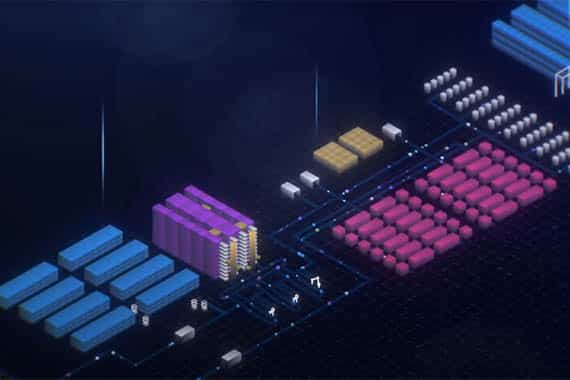

At Savoye, the digital twin is an application that makes it possible to represent, in 2D or 3D, the equipment in a logistics warehouse. Why is this useful? This digitization of the physical warehouse makes it possible to validate several features of the WCS (Warehouse Control System) management software, before it is rolled out on site. This twin is the exact representation of the customer’s warehouse. Directly connected to the WCS, it makes it possible to carry out end-to-end tests, which check that the application is working as intended under normal operating conditions, but it can also simulate a large range of events that may occur during use (breakdowns, input errors, etc.) and therefore make the solution more resilient.

This makes it possible to monitor the progress of a package within the logistics platform: from the moment the message is received from the WMS until it can be seen passing through the picking stations, inspection stations and packaging and shipping zones. The digital twin also makes it possible to simulate a large number of events more quickly, thereby making it possible to analyze the behavior of applications over several days of intense use in a timeframe that is reduced to a few hours.