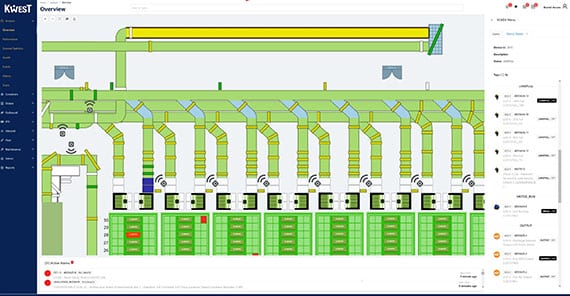

KWEST makes it simple to integrate various automated and robotic equipment.

Shuttles, robots, ASRS, sorters, picking stations, pick-to-light systems, etc. KWEST can take the control of any equipment within the warehouse execution system. KWEST ensures both SAVOYE’s equipment and third-party systems can be integrated while still using the backend execution engine for base functionality.

“Connected through one single WMS interface, KWEST relieves the warehouse equipment users from multi-supplier interfaces.” Explains Mike Rossi, sales director.

KWEST constantly optimizes the warehouse running performance.

KWEST orchestrates and coordinates all the warehouse subsystems. It intelligently sequences orders depending on customer driven priority constraints, the operator’s efficiencies, and the physical equipment capacity. It also automatically estimates the lead time to complete and releasing work to account for all activities necessary for the order – picking, inventory, replenishment, temporary storage before packing or palletizing, etc.

This high performance is driven by the constant load balancing of the logistic flows, optimizing containers paths within the warehouse.