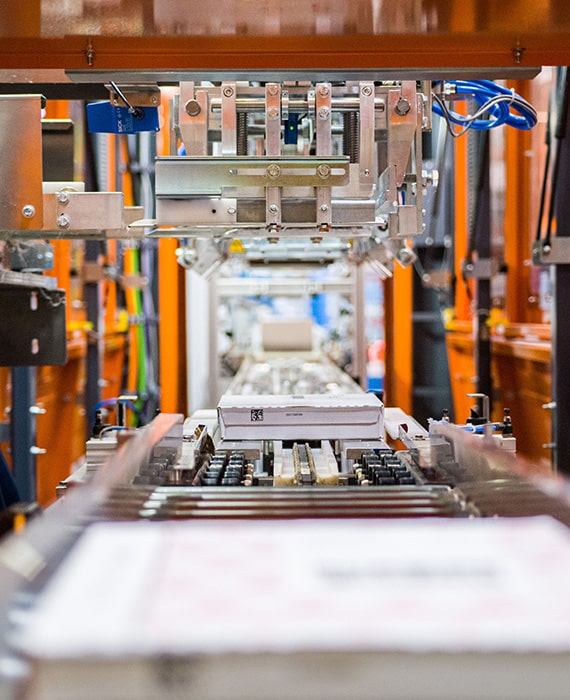

In the light of the above and to ensure good warehouse performance and responsiveness, automating the packaging process is a relevant solution for reaching high quality and service goals. To achieve this, packaging automation must go hand in hand with specific responses to the reduction of unused space in the parcels and the securing and wedging of the products. There are 4 main reasons to automate your packaging processes:

- TO INCREASE WAREHOUSE PRODUCTIVITY

- TO IMPROVE ECONOMIC PERFORMANCE

- TO DEVELOP A VECTOR FOR CUSTOMER SATISFACTION

- TO REDUCE PACKAGING VOLUME