Why Savoye

- Specific expertise of the spare parts sector

- Comprehensive turnkey solution

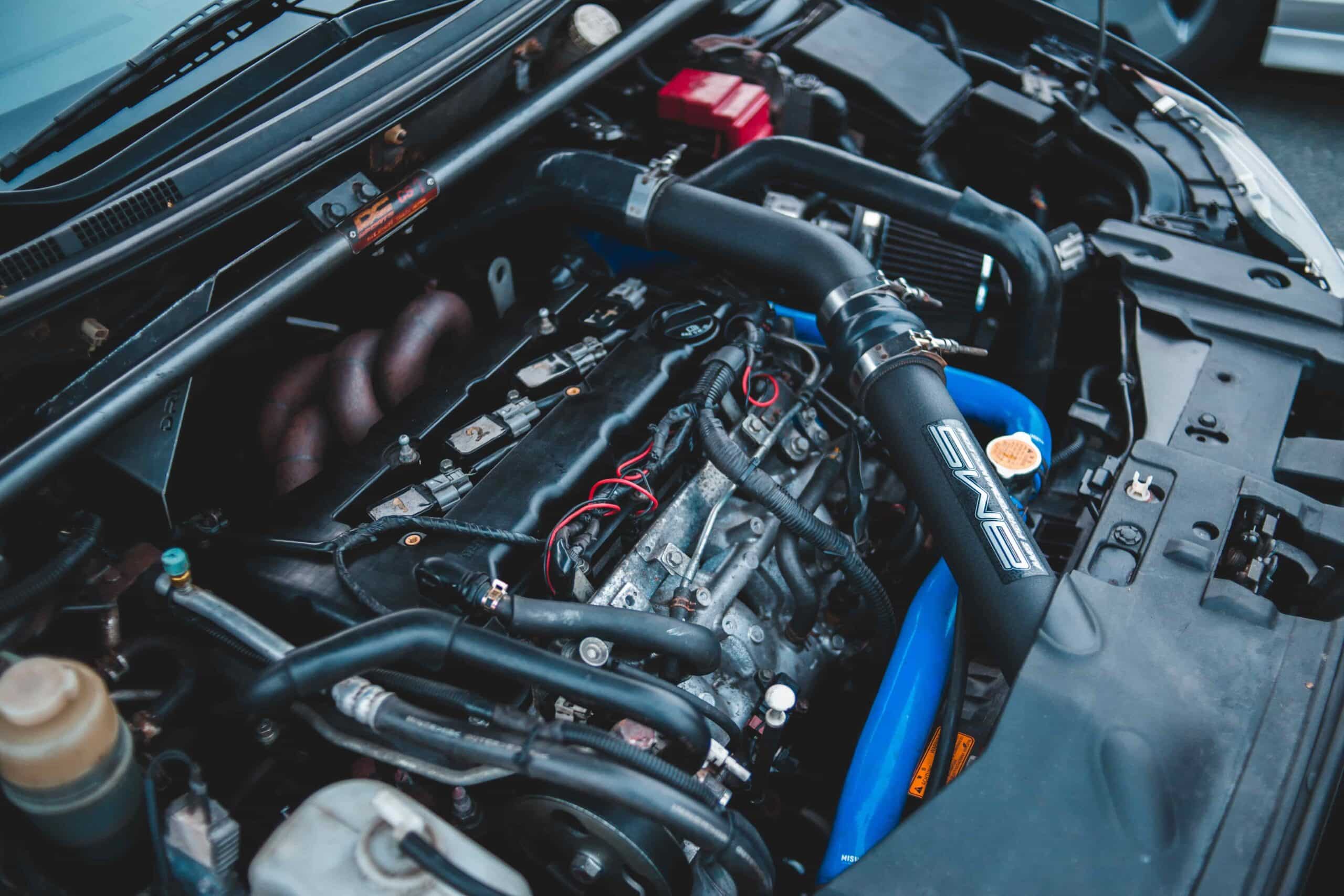

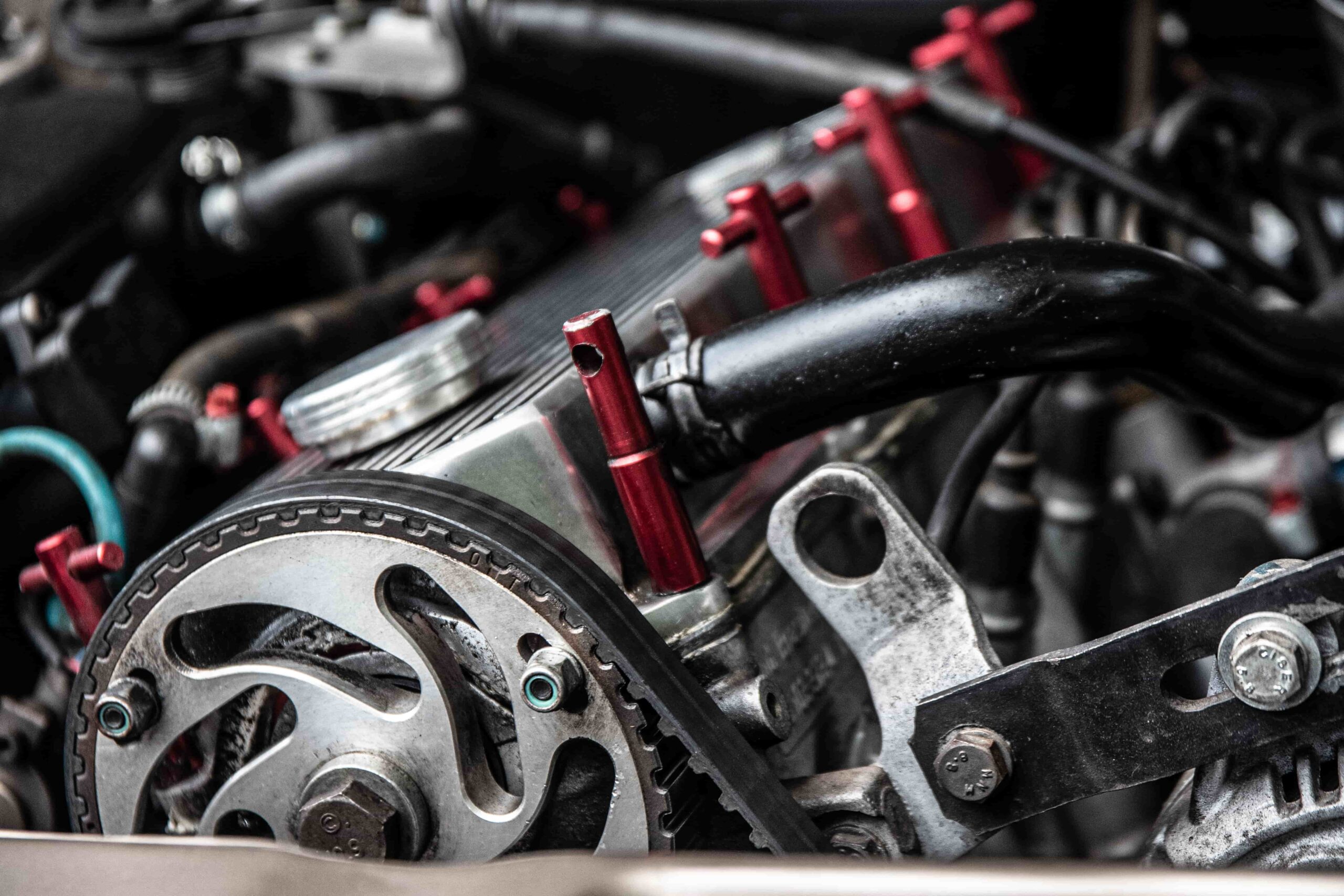

Keen to meet the demands of its clients more efficiently and to make the distribution of its products more reliable, Flauraud, a PGA subsidiary, chose SAVOYE to automate its 16,000 m2 site.

Our SAVOYE teams’ expertise in the spare parts sector enabled us to offer Flauraud a comprehensive, turnkey solution.